Ethylene Propylene Diene Monomer, widely recognized as EPDM, stands out for its superior resistance to UV rays, ozone, and extreme weather conditions. These qualities, combined with its excellent flexibility at low temperatures, make EPDM a preferred choice for outdoor applications. Its resistance to polar substances and steam further broadens its application range.

EPDM, or Ethylene Propylene Diene Monomer, is a versatile synthetic rubber compound with a remarkable range of applications. Its unique properties make it a sought-after material in various industries, from automotive to construction. In this article, we’ll dive into the world of EPDM, exploring its characteristics, manufacturing process, and the myriad ways it contributes to innovation and sustainability.

EPDM is renowned for its outstanding resistance to weathering, ozone, and UV radiation. This durability makes it an ideal choice for outdoor applications, including automotive weatherstripping, roofing membranes, and even playground surfaces. Its ability to withstand extreme temperatures, from scorching summers to freezing winters, sets it apart from conventional rubber.

The production of EPDM involves the copolymerization of ethylene, propylene, and a diene comonomer. This process yields a versatile material that can be fine-tuned to meet specific requirements. The result is a synthetic rubber that offers exceptional resistance to heat, oxidation, chemicals, and electrical conductivity.

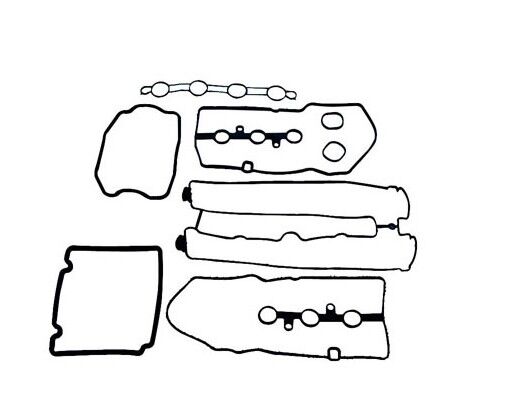

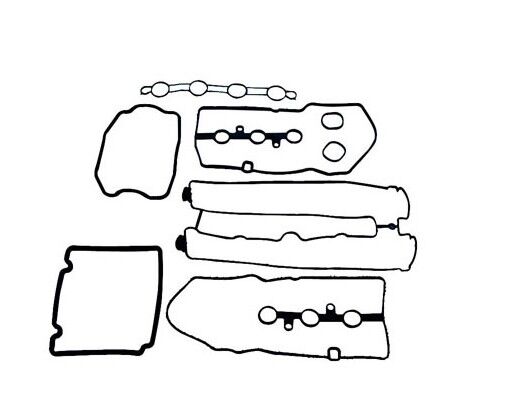

In the automotive sector, EPDM plays a pivotal role in ensuring vehicle performance and longevity. EPDM rubber seals are used extensively in automotive manufacturing for weatherstripping, door seals, and window seals. These seals provide a secure barrier against environmental factors, such as rain, dust, and noise, contributing to passenger comfort and safety.

EPDM’s environmental benefits are equally impressive. Its long service life and resistance to environmental stressors translate into reduced waste and lower maintenance costs. EPDM roofing, for instance, can last for decades with minimal upkeep. Additionally, EPDM is fully recyclable, aligning with the global push for sustainable materials.

Beyond traditional applications, EPDM’s versatility shines in unique sectors. It’s a preferred material for pond liners, as it doesn’t release harmful substances into aquatic environments. EPDM is also used in geothermal systems, where it efficiently transfers heat in underground pipes, contributing to energy efficiency.

As we navigate an era where sustainability and performance are paramount, EPDM stands as a shining example of innovation. Its remarkable properties, versatility, and eco-friendliness make it a material of choice across diverse industries. From keeping our cars dry to roofing our homes sustainably, EPDM’s impact is undeniable. As technology advances and environmental consciousness grows, we can expect even more ingenious applications for this extraordinary synthetic rubber.